We are a long way away from fully capturing the benefits of the Fourth Industrial Revolution (4IR) in an inclusive and holistic way. To do this, technology adoption and diffusion across the ecosystem needs to improve dramatically.

We are a long way away from fully capturing the benefits of the Fourth Industrial Revolution (4IR) in an inclusive and holistic way. To do this, technology adoption and diffusion across the ecosystem needs to improve dramatically.

In a recent report, jointly from the World Economic Forum and McKinsey called the “The Fourth Industrial Revolution and the factories of the future” they made a number of observations

“After a decade of flat productivity, the arrival of the Fourth Industrial Revolution (4IR) is expected to create up to $3.7 trillion in value to global manufacturing. A few years back, experts noted that the changes associated with the 4IR would come at an unprecedented rate yielding incredible results for those who truly embraced them.

Still, the hockey stick of benefits has not kicked in yet – while all companies are making efforts to adopt technology, most of the production industry (~70%) remains in pilot purgatory (where technology pilots last for extended periods of time, and companies do not take the final step of scaling up viable technologies). Less than 30% of manufacturing companies are actively rolling out Fourth Industrial Revolution technologies at scale”

No wonder we presently have trouble attracting many businesses onto platforms when they are still very much behind in deciding or deploying a strategically thought-through IIoT digital design, that is connecting everything up.

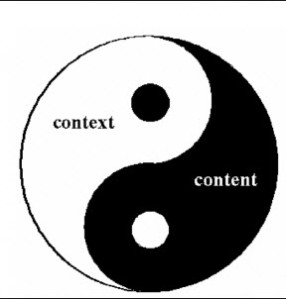

It is equally holding a new form of innovation back, one that is highly collaborative where partners come together to work on more complex problems. Collaborators can achieve solutions only by being “fully” connected up, comfortable with their data, understanding and contribution, both within their knowledge and insights.

The power of multiple-connected ecosystems gives innovation a completely different momentum but it needs this 4th industrial revolution to be fully operative, for a digitally connected world in manufacturing and beyond.